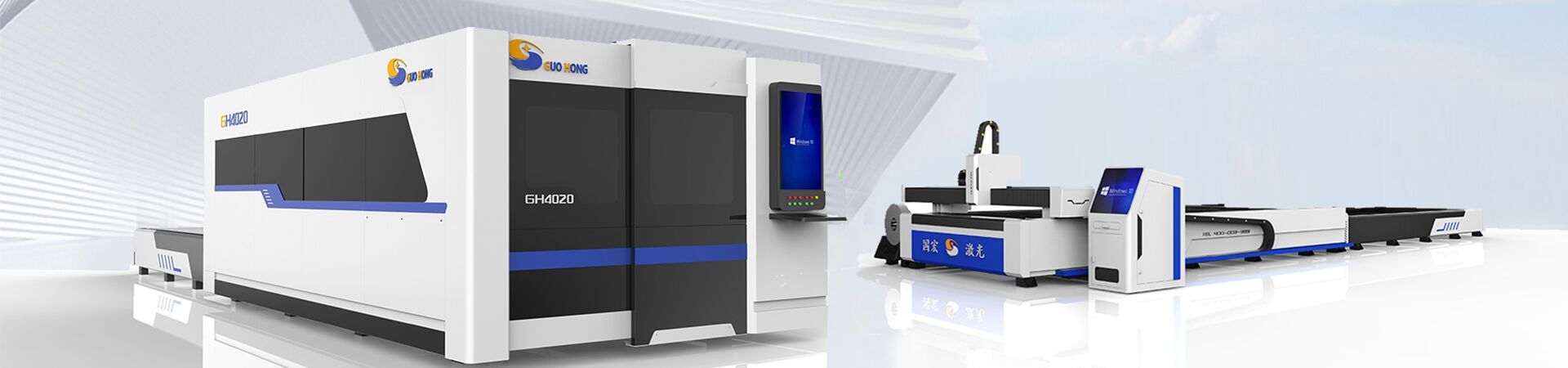

Ib Leeg Platform Phaj thiab Tube Laser Tej Tshuab

Kev piav qhia:

Tib lub platform phaj thiab lub raj laser txiav tshuab

Ib lub tshuab nrog ob txoj haujlwm, kev siv tshuab ua tau zoo tshaj plaws

Guohong laser tib lub platform phaj thiab lub raj laser txiav tshuab tuaj yeem txiav cov hlau feem ntau (cov menyuam). lub tshuab ua kom haum cov khoom siv tau ua ke nrog kev tsim qauv, nrawm nrawm thiab sib dhos, sab laug thiab sab xis kev lom zem txais cov khoom, txuag chaw. Nws yog qhov tshwj xeeb hauv kev txiav 0.5-14 hli carbon steel phaj (raj) 0.5-5 hli stainless hlau phaj (raj) galvanized phaj (raj) electrolytic phaj (raj) silicon steel thiab lwm yam ntaub ntawv hlau me, yeeb nkab inch 20-150mm.

Aerospace txhuas gantry

Lub aerospace txhuas yog tsim nyob rau hauv cov qauv aerospace. Tom qab tsim kev laus cuav thiab kev daws teeb meem, nws tiav lawm. Hardness tau mus txog rau T6, thiab nws muaj cov yam ntxwv ntawm kev ua kom nruj thiab ductility.

Lub teeb nyob rau hauv qhov hnyav, yooj yim rau kev kub ceev thaum lub sij hawm ua, thiab yog hloov tau yooj yim. Nws tuaj yeem nce qhov kev coj ua ceev ceev thaum qhov tseeb ntawm tau ntsib.

Autofocus Txiav Lub Taub Hau

Tsis siv neeg puv-ob chav Pneumatic Chuck

Ib-khawm clamping, nws pib kho, 3 zaug nrawm dua li hluav taws xob chuck, txuag lub sijhawm tos rau kev thau khoom thiab tawm haujlwm; Pneumatic claws nrog lub zog loj thiab tsis tu ncua clamping quab yuam, hnyav lub raj yog clamped nruj nreem tsis plam, txiav qhov tseeb lav; Cov tshwj xeeb txhawb nqa txwv tsis pub tub raj los ntawm sagging thiab deforming, txhim kho kev txiav kom raug thiab lub neej ntev kev pab cuam ntawm chuck.

Zoo siab Carbon Steel Vuam Tshuab ua txaj

Kev Txawj Ntse Saib Xyuas Lub Cev

PARAMETERS

| Tshuab qauv | GHJG-3015 ◆ GHJG4015 ◆ GHJG4020 ◆ GHJG-4025 | ||

| Cov chaw ua haujlwm | 1500x3000mm ◆ 1500x4000mm ◆ 2000x4000mm ◆ 2500x4000mm | ||

| Max. Zog Ceev | 70m / min | ||

| Ua nrawm nrawm | 0.6G | ||

| Muab tso rau qhov tseeb ntawm | 0.03 hli | ||

| Rov ua dua | 0.02mm | ||

| Siv fais fab | 1000W-60000W | ||

Txiav qauv

Nta cov tshuab :

1. ib lub tshuab thiab ob lub tshuab tuaj yeem txiav ob daim hlau thiab cov kav dej, lub tshuab ua haujlwm zoo tshaj plaws.

2. kev pib thoob ntiaj teb rau kev tsim qauv yooj yim thiab kev koom ua ke: laser cua txias chav tsim qauv nrog kev pab lub neej ntev dua.

3. lub tshuab dhos txaj adopts 600 ℃ siab kub kev kho cua sov, 12 meters gantry milling thiab xov, thiab txias nrog lub cub tawg 24 teev rau xyuas kom meej tias lub tshuab tsis deform tom qab siv sijhawm ntev.